Designing a catalyst is incredibly difficult – yet researchers at Tohoku University have successfully created a catalyst that is ranked as one of the best. Their catalyst greatly speeds up the oxygen evolution reaction (OER), which is a typically slow-paced reaction that desperately needs a boost so that it can be used practically in environmentally friendly technologies. This result combines low overpotential, long-term stability, and practicality into a catalyst that has a promising future helping us combat climate change.

The findings were published in Journal of the American Chemical Society on August 20, 2025.

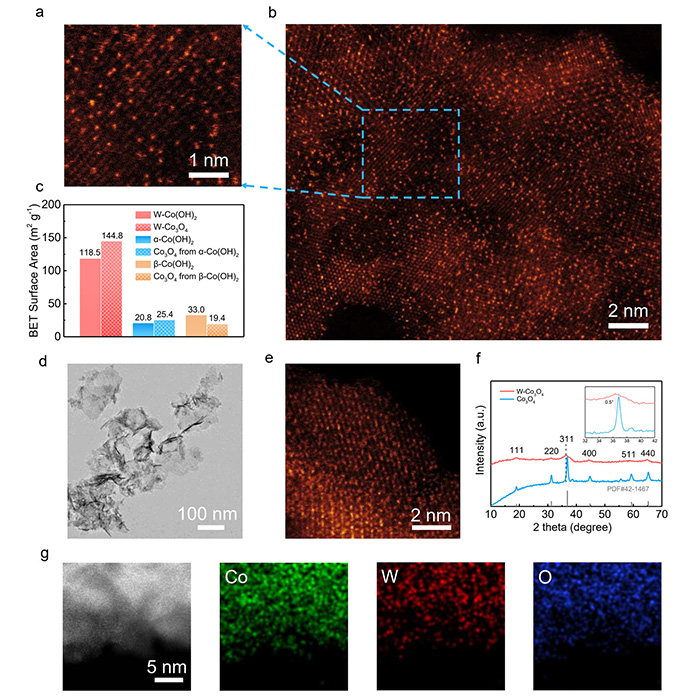

Characterizations of W-Co(OH)x and W-Co3O4. (a, b) Aberration-corrected HAADF-STEM images of W-Co(OH)x. (c) BET areas of W-Co(OH)x, α-Co(OH)x, β-Co(OH)2 and their corresponding oxides. (d, e) TEM and aberration-corrected HAADF-STEM images of W-Co3O4. (f) XRD patterns of W-Co3O4 and the pure Co3O4 prepared from α-phase cobalt hydroxide. (g) EDS elemental mapping of W-Co3O4. ©Yong Wang et al.

What makes designing catalysts so difficult is obtaining the right balance of traits that speeds up the OER as much as possible while minimizing negative tradeoffs. For example, while more active sites are desirable, too many can compromise the composition and structure of the catalyst – making it unstable.

The key to their success was tungsten (W) and a general oxygen-vacancy anchoring strategy. Their method enabled the high-density and stable incorporation of W single atoms into transition-metal hydroxides/oxides. This stabilizes ultrathin structures, while also allowing for more active sites that speed up the reaction. This technique breaks the conventional trade-off between activity and stability.

“This research is important as it contributes to the development of more efficient and cost-effective catalysts for water electrolysis, a key process for producing clean hydrogen fuel.” explains Professor Hao Li (WPI-AIMR).

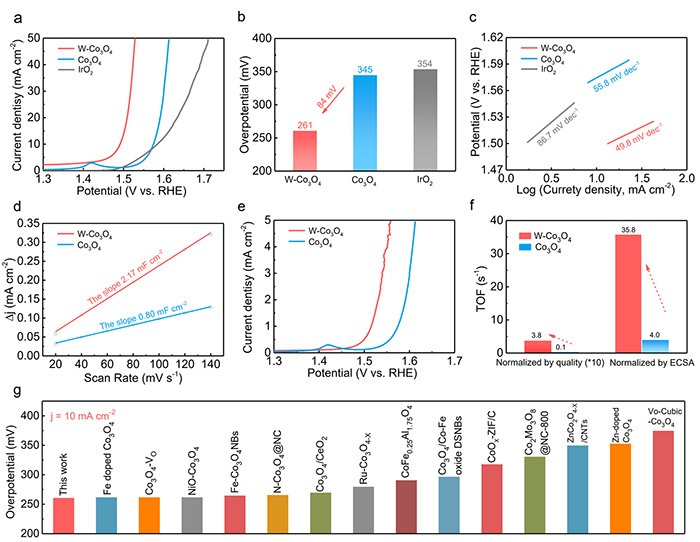

OER catalytic activity of W-Co3O4 in alkaline environment. (a–c) iR-corrected polarization curves, overpotentials required for j = 10 mA cm–2, and the corresponding Tafel plots of W-Co3O4, Co3O4 and IrO2. (d) Current densities in CV plotted against scan rates for W-Co3O4 and Co3O4 (the linear slope is twice Cdl). (e) iR-corrected polarization curves normalized by ECSA of W-Co3O4 and Co3O4. (f) TOFs at 1.58 V normalized by mass or ECSA of W-Co3O4 and Co3O4. (g) η10 comparisons of W-Co3O4 and state-of-the-art cobalt oxide-based OER electrocatalysts. ©Yong Wang et al.

This work provides a low-cost, robust, and efficient alternative that does not depend on expensive noble metals or unstable Fe-based systems. The research team says their next steps will further evaluate the long-term stability of the catalysts under industrially relevant current densities, and explore their performance in practical applications such as Anion Exchange Membrane Water Electrolysis and Zn–air batteries. These efforts will accelerate the translation of our findings into cost-effective, durable OER catalysts for renewable energy conversion and storage technologies.

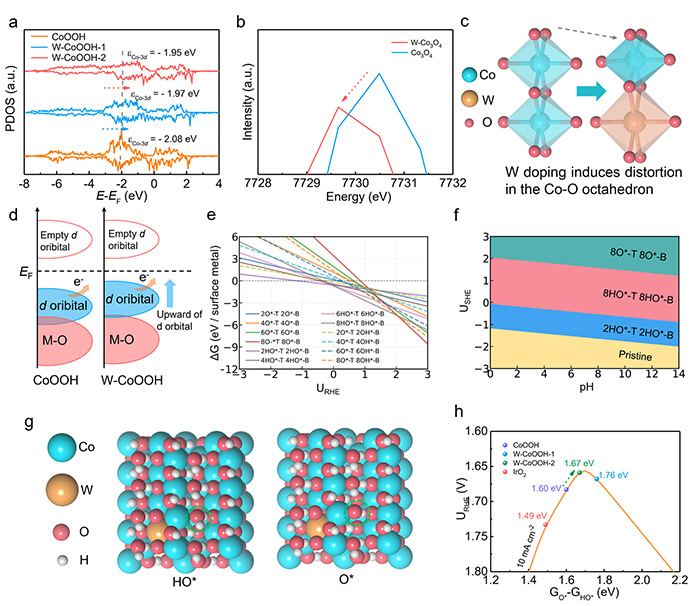

Theoretical analyses of OER activity on W-CoOOH. (a) Projected density of states of CoOOH, W-CoOOH-1 and W-CoOOH-2 (EF: Fermi level; ɛCo-3d: Co 3d band center). (b) The white line intensities in the Co K-edge XANES spectra. (c) Illustration of the Co-O octahedron distortion in W-CoOOH and CoOOH. (d) Schematic band diagrams of CoOOH and W-CoOOH. (e) Stability of O* and HO* on W-CoOOH-2. (f) 2D surface Pourbaix diagram of W-CoOOH-2. (g) Optimized adsorption structures for HO* and O* (top view) on W-CoOOH-2 pre-covered by hydroxyls. (h) Microkinetic OER volcano at the current density of 10 mA cm−2, with the points indicating the OER potentials. ©Yong Wang et al.

| タイトル: | High-density W single atoms in two-dimensional spinel break the structural integrity for enhanced oxygen evolution catalysis |

|---|---|

| 著者: | Yong Wang, Baorui Jia, Wanjun Qin, Yuhang Wang, Sijia Liu, Yunpu Qin, Yongzhi Zhao, Luan Liu, Di Zhang, Heng Liu, Haoyin Zhong, Jianfang Liu, Juping Tu, Yadong Liu, Haoyang Wu, Deyin Zhang, Jun Fan, Xuanhui Qu, Hao Li, Mingli Qin |

| 掲載誌: | Journal of the American Chemical Society |

| DOI: | 10.1021/jacs.5c12122 |

東北大学材料科学高等研究所(WPI-AIMR)

教授 Hao Li(研究者プロフィール)

| E-mail: | li.hao.b8@tohoku.ac.jp |

|---|---|

| Webstie: | Hao Li Laboratory |

東北大学材料科学高等研究所(WPI-AIMR) 広報戦略室

| Tel: | 022-217-6146 |

|---|---|

| E-mail: | aimr-outreach@grp.tohoku.ac.jp |