11/28/2016

Reproduced from Ref. 1 and licensed under CC BY 4.0 © 2016 S. Yaginuma et al.

By mathematically analyzing the nanostructures of metallic glasses, AIMR researchers have gleaned new insights into how these useful materials form. This knowledge will help to optimize the manufacturing process.

Metallic glasses are attracting a lot of interest because their disordered structures give them different properties from conventional metals, which have highly ordered structures. In particular, nanowires made from metallic glasses are promising for use in magnetic sensors, fiber-reinforced composites and heterogeneous catalysts.

Koji Nakayama of the AIMR at Tohoku University and co-workers previously demonstrated that metallic glass nanowires can be produced by gas atomization — a common process for the commercial production of metal and alloy powders. In this method, a molten metal is ‘atomized’ into small droplets by high-speed jets of a chemically unreactive gas. But the complexity of the atomization process makes it difficult to control the sizes and shapes of metallic glass nanowires.

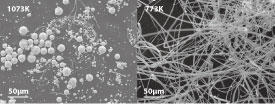

Now, by teaming up with mathematicians at the AIMR, Nakayama’s group has statistically analyzed the formation of microdroplets and nanowires made from a palladium-based metallic glass1. They found that the forms of the droplets and wires are related to a parameter known as the Ohnesorge number, which relates the viscous forces of a fluid to its surface tension forces. In particular, microdroplets form at low values of the Ohnesorge number, whereas nanowires are produced at higher values (see image).

The researchers also found that the distribution of nanowire diameters follows a well-known statistical pattern in nature, called the log-normal distribution. “The log-normal distribution is defined as the distribution of a random variable whose logarithm is normally distributed,” explains Nakayama. “It has been widely applied for fitting data such as the sizes of organisms, the numbers of species in biology and incomes in economics.”

These findings will assist researchers to develop a clearer picture of how nanowires of metallic glasses form during gas atomization, which will eventually lead to better control of the process.

The researchers selected palladium-based metallic glass for the study because of its strong glass-forming ability and high resistance to reacting with oxygen, but Nakayama notes that the same analysis can be carried out on other metallic glasses.

Nakayama values mathematicians’ input to the analysis. “The study was done with the support of the AIMR Fusion Research Program, which promotes cross-disciplinary research between materials science and mathematics to gain new insights into industrial products,” says Nakayama. “Collaboration with mathematicians was vital because they helped us to develop the statistical models.”

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.