09/26/2016

Reproduced from Ref. 1 and licensed under CC BY 4.0 © 2016 F. Zhu et al.

Despite being stronger than steel, metallic glass alloys suffer from a heating-induced brittleness that limits their use in practical applications. A team from the AIMR has now used dynamic microscopy techniques to shed light on nanoscale structures that play key roles in determining the properties of metallic glasses1.

Metallic glasses are made by supercooling molten metal atoms, such as zirconium, aluminum and copper, so that they form tightly packed solids with random molecular structures instead of regular crystals. When the atoms are taken out of their high-energy state, they mechanically relax through two processes: α- and β-relaxations. Primary α-relaxations disappear as the mixture is cooled below its glass transition temperature, whereas secondary β-relaxations keep occurring well after the alloy has been cast — these atom movements can lead to ‘aging effects’ as well as permanent plastic deformation.

Despite their importance, β-relaxations are only partially understood. Theoretical models indicate that spatial non-uniformity in the glass is responsible for aging effects, but corroborating experimental evidence had been missing. “It’s a dynamic process, so the key obstacle is designing a characterization experiment that can catch such a time-dependent phenomenon,” says Fan Zhu from the AIMR at Tohoku University.

Zhu, Mingwei Chen and their colleagues developed a technique to tune the degree of β-relaxations in a metallic glass by heating at temperatures below the glass transition point for varying lengths of time. They then characterized the samples using amplitude-modulation atomic force microscopy (AM-AFM) and scanning transmission electron microscopy (STEM) to see any disruption of nanoscale structures.

While most AFM experiments use a tiny vibrating cantilever to trace the height of surface atoms, AM-AFM measures variations in the amplitude and phase of the oscillating tip. These dynamic tip movements, explains Zhu, are very useful for measuring how metallic glasses behave both as elastic solids that snap back into shape after being twisted and as viscoplastic materials whose atoms can permanently flow into new locations.

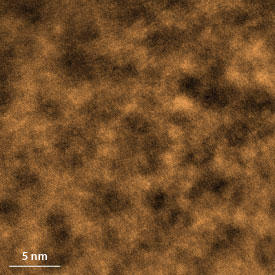

By comparing the structural characteristics of relaxed metallic glasses with those of a hypercooled metallic glass, the team found that atomic movements were confined to small, isolated regions during β-relaxation. These regions were clear enough to resolve in STEM images as contrasting dark and bright regions, just a few nanometers in diameter (see image).

Zhu notes that this establishment of a definite link between β-relaxations and nanoscale inhomogeneous zones can aid researchers to exploit the unique properties of amorphous materials. “With this structural scheme, we can fill in the knowledge gaps between the properties and models of glasses,” he adds.

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.