11/21/2014

© 2014 Yoshiyuki Kikuchi

A new technique for creating amorphous hydrocarbon films that employs much milder conditions than conventional methods has been applied by Yoshiyuki Kikuchi and colleagues of Samukawa’s and Matsue’s laboratories to fabricate electrodes for electrochemical sensors1.

Amorphous hydrocarbon films are promising for use as components in biomedical sensors, as they are biocompatible, chemically stable and conduct electricity well. These properties make them suitable as electrode coatings in such sensors. But conventional techniques for creating amorphous hydrocarbon films require high temperatures and plasma — a gaseous soup of charged particles — both of which can damage the semiconductor substrates beneath the films.

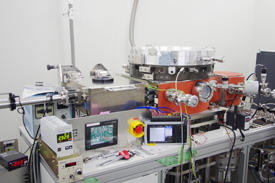

The new technique uses two reaction chambers separated by a perforated barrier (see image). Argon gas is injected into the upper chamber, where microwaves excite it to form a plasma containing positive argon ions. Meanwhile, the carbon-based compound toluene is injected into the lower chamber, from where it leaks into the upper chamber through the holes in the barrier.

The positive argon ions partially break up the toluene molecules, which then return to the lower chamber and adsorb on a silicon substrate at a temperature of –50 degrees Celsius. Argon ions follow the same path, but pick up an electron as they pass through the perforated barrier, creating a stream of neutral argon atoms; this neutralization technology of argon was developed by Seiji Samukawa’s group at Tohoku University in 2000. These atoms hit the carbon-based fragments stuck to the silicon, helping to knit the molecules together into a continuous film. Crucially, the perforated barrier blocks any ultraviolet light emitted by the plasma, which would otherwise damage the precursor molecules and substrate.

The researchers, who are from the AIMR, Tohoku University, found that the film was composed of an interconnected network of molecules called polyaromatic hydrocarbons and could conduct electricity reasonably well. Tests showed that the film had a low electrical resistance and fast electron transfer, ideal properties for an electrochemical sensor.

The team improved the technique by producing just the right balance of pressures between the two chambers, to enable ideal mixing of argon and toluene. They also boosted the film’s conductivity by adding nitrogen gas to the argon stream — this probably resulted in nitrogen atoms being incorporated into the finished film, a process called nitrogen doping that helps make the material’s electrons more mobile. “Nitrogen doping improves the electrode performance,” explains Kikuchi.

The researchers are currently collaborating with another group to develop an amorphous hydrocarbon electrode for a sensor that could be used for a range of bioimaging applications, such as tracking the release of neurotransmitters from neurons.

Kikuchi, Y., Wada, A., Kurotori, T., Nakano, M., Inoue, K. Y., Matsue, T., Nozawa, T. & Samukawa, S. Conductive amorphous hydrocarbon film for bio-sensor formed by low temperature neutral beam enhanced chemical vapor deposition. Carbon 67, 635–642 (2014). | article

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.