10/27/2014

Reproduced, with permission, from Ref. 1 © 2014 American Chemical Society

Small variations in mixing at polymer interfaces can have a large effect on how devices such as photovoltaic cells and membranes perform. Dong Wang from the AIMR at Tohoku University and colleagues have used an innovative technique known as quantitative nanomechanical mapping (QNM) to simultaneously acquire microstructural and mechanical information on polymer interfaces1. This information may make solving future adhesion problems significantly simpler.

One of the fundamental issues facing manufacturers of polymer-based devices is quantifying how different layers diffuse and entangle together after processing treatments. Many analytical techniques have been developed to study the interpenetration of long molecular chains into each other’s domains. However, most of these methods provide only the concentration gradients of different components. The interfacial mechanical properties, which are tightly linked to a polymer’s applications, are difficult to measure at small scales.

Wang and colleagues turned to the capabilities of atomic force microscopy (AFM) to detail the unique physics of polymer interfaces. Normally, researchers use resonant ‘tapping’ signals from an AFM probe to trace out detailed, three-dimensional profiles of scanned surfaces. These tapping signals can also gauge the mechanical forces between a polymer and the probe. But such AFM force modes have slow data acquisition rates and require non-trivial analytical techniques to convert the measured mechanical forces into material properties.

The newly developed QNM imaging mode for AFM dramatically speeds up and simplifies mechanical measurements by detecting the maximum force applied to a surface during a probe tap. Then, by using this ‘peak force’ signal as a damage-preventing feedback control loop, the tapping signals can scan rapidly across a sample and map out regions of different physical force with nanoscale precision.

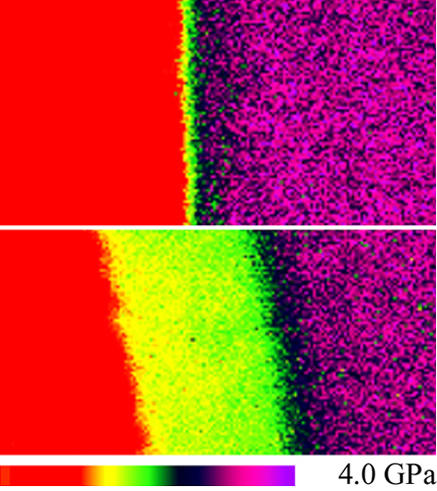

The researchers examined interfaces formed between poly(vinyl chloride) and poly(n-butyl methacrylate), two plastics that are fully mixable, to test for diffusion-induced effects with QNM. The resulting nanomechanical maps revealed clear stiffness signatures of the polymer components and a distinct bulge at the interface (see image). By tracking how this zone broadened and mechanically deformed over time, the team acquired a wealth of new physical and chemical data: the interface’s diffusion kinetics, microstructures and glass transition temperatures were identified with a ten-nanometer resolution.

“What is most striking about this method is its ability to assess small differences in the mechanical properties of materials over very short length scales using high-resolution AFM,” says Wang. “This has not been possible previously and provides a new route to investigate the bonding between polymer multilayers.”

Wang, D., Liang, X., Russell, T. P. & Nakajima, K. Visualization and quantification of the chemical and physical properties at a diffusion-induced interface using AFM nanomechanical mapping. Macromolecules 47, 3761–3765 (2014). | article

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.