12/20/2013

Reproduced, with permission, from Ref. 1 © 2013 K. Madhav Reddy et al.

Boron carbide (B4C) is a superhard yet lightweight ceramic material. As a result of these characteristics, it is used as a protective component in bulletproof vests and tank armor and also has many other industrial applications. Despite its hardness, boron carbide’s crystalline structure deforms under shear pressure, which creates amorphous regions that lead to the failure of the material. The precise mechanism behind this destructive amorphization, however, remains unclear.

Now, Mingwei Chen, Madhav Reddy and colleagues from the AIMR at Tohoku University have used Cs-corrected scanning transmission electron microscopy (STEM) to investigate the atomic-level deformation processes that take place during the formation of amorphous shear regions in boron carbide1. “Understanding such processes is important for the design and development of new boron carbide-based materials with improved impact performance,” says Chen. “It is also important for understanding the basic failure processes of a covalent material.”

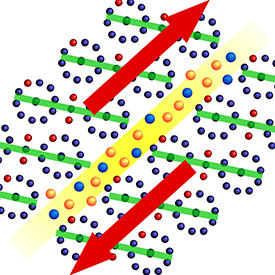

The crystalline structure of boron carbide comprises 12-atom icosahedra and 3-atom carbon–boron–carbon chains located within individual crystal planes. Under shear pressure, amorphous bands approximately 2 nanometers wide are created, which form within the plane containing the carbon–boron–carbon chains (see image).

Using a technique known as annular bright-field (ABF) imaging, which allows light elements to be observed at high spatial resolutions, Chen and his colleagues probed the finer details of the shear bands. The researchers were able to identify atomic-scale changes, which led them to conclude that the shear bands were formed from disassembly of the icosahedra.

At the interface of the crystalline regions and the amorphous zone, the team observed deformed icosahedra. While some icosahedra were displaced from their original position by a considerable distance, others were hardly displaced at all, indicating that the conversion from a crystalline to an amorphous structure is progressive within the material. In the amorphous band, the icosahedra were irregularly shaped, randomly located and also lower in number than in the bulk of the material. The latter may either be due to the collapse of icosahedra during shear band formation or limitations of the ABF-STEM imaging technique when observing tilted icosahedra.

“Our findings could help to fabricate boron carbide materials with improved mechanical properties by reinforcing atomic chains through chemical doping or changing the boron/carbon ratio,” says Chen. “We are now focusing on structural characterization and modification of the atomic chains in boron carbide by utilizing advanced Cs-corrected STEM and developing boron-rich boron carbide and heavily doped boron carbides.”

Madhav Reddy, K., Liu, P., Hirata, A., Fujita, T. & Chen, M. W. Atomic structure of amorphous shear bands in boron carbide. Nature Communications 4, 2483 (2013). | article

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.