12/21/2012

© 2012 Nature Publishing Group

Despite being hard enough to repel bullets, boron carbide ceramics suffer from a critical brittleness that leads them to fracture at low stress levels. However, an international team of researchers led by Mingwei Chen from the AIMR at Tohoku University1 has now discovered a way to enhance the durability of boron carbide by synthesizing it into a ‘nanocrystalline’ ceramic with plastic deformation capabilities. Surprisingly, this increased toughness arises from the distribution of small pores and amorphous interfaces — factors that normally weaken ceramic materials.

Commonly, ceramics are made through the process of sintering which heats compressed powders to a temperature just below their melting point. Although this produces a very hard substance, it also generates a variety of crystal grain structures, which may act as fracture initiation points. Chen and his co-workers decided to take a different approach to synthesis: under a lower sintering temperature, they used intense pressures to fuse the boron carbide crystallites into uniform grain sizes, with the expectation that this would reduce brittleness.

High-resolution electron microscopy and X-ray diffraction characterization of the nanocrystalline boron carbide allowed the team to observe the fine-grained structure of the ceramic. They were amazed to spot tiny, irregularly-shaped holes — nanopores — throughout, as well as thin, amorphous carbon layers coating the crystal and nanopore surfaces. Chen explains that these flaws probably appear because they cannot be completely driven away by the reduced temperatures during sintering.

Mechanical experiments revealed this new ceramic to be tougher than any boron carbide seen before — able to withstand indentation pressures of up to 75% higher than those of conventional materials. Re-examination of the deformed ceramic showed that while the crystal grains remained intact, the nanopore population had severely diminished. This led the team to postulate that the pores and carbon layers help to lubricate the crystal grains, enabling them to slide during compression and therefore tolerate greater pressures.

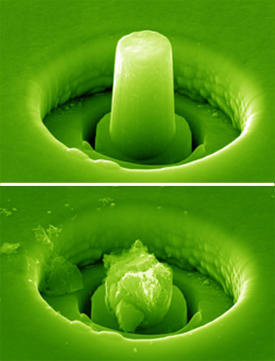

By carving individual micropillars from the nanocrystalline boron carbide ceramic (see image), the researchers were able to see the effects of indentation first-hand. At high compression pressures, the micropillars bent plastically like a metal instead of shattering — an unprecedented observation for this type of hard material. “This new plastic deformation mode can effectively dissipate the energy of crack tips — preventing crack growth,” says co-author and PhD student Madhav Reddy.

According to the researchers, the enhanced toughness of the nanocrystalline boron carbide should benefit applications ranging from cutting tools to body armor. They are currently exploring if their strengthening strategy can be expanded to other hard ceramics, such as silicon carbide.

Reddy, K. M., Guo, J. J., Shinoda, Y., Fujita, T., Hirata, A., Singh, J. P., McCauley, J. W. & Chen, M. W. Enhanced mechanical properties of nanocrystalline boron carbide by nanoporosity and interface phases. Nature Communications 3, 1052 (2012). | article

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.