12/21/2012

© 2012 Taro Hitosugi

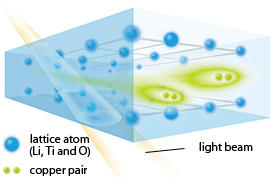

Oxide alloys exhibit intriguing physical properties, such as superconductivity and magnetism, which make them promising components for a wide range of devices including transistors and batteries. Control of the stoichiometry of these materials is an essential requirement for achieving high performance. Now, Taro Hitosugi, Takeo Ohsawa and co-workers at the AIMR have studied the growth of two interesting spinel lithium titanate oxides1. Their careful observations have allowed them to optimize the stoichiometry of these materials, leading to the production of superconducting thin films which also have a high level of transparency.

High-quality oxide films are usually produced by a method known as pulsed laser deposition (PLD). The technique involves hitting a structurally and compositionally low-quality oxide alloy with high intensity laser pulses, so that it vaporizes and subsequently re-deposits onto a substrate. Hitosugi and co-workers were particularly interested in LiTi2O4, a spinel oxide known to exhibit superconductivity below 13.7 K, and its close relative Li4Ti5O12, which is commonly used as an electrode in lithium-ion batteries.

Previously the researchers observed that the films obtained by PLD tend to have much lower lithium content than their precursor materials. They also noticed that the oxygen pressure during growth plays an important role in the resulting film’s composition.

The team selected Li4Ti5O12 as a target for PLD and fabricated various films at different oxygen pressures in a growth chamber. At high oxygen pressure a Li4Ti5O12 film was obtained — but at low oxygen pressure the lithium content became depleted, resulting in the deposition of LiTi2O4 instead. This means that, depending upon the oxygen pressure, the thin film growth occurs through two different mechanisms which influence the lithium/titanium ratio and, in turn, the structure and composition of the material deposited.

The PLD-grown oxide films are of an exceptionally high quality, as exemplified by the high electrical conductivity, 3x103 S/cm, of the LiTi2O4 film at room temperature. A transparency of up to 70% makes them particularly promising for use in touch screen displays and flat panel displays, as well as for the realization of transparent electrodes for solar cells. In addition, they exhibit a superconducting temperature of 13 K — a record high for such a thin film. The films could also hold potential for quantum information applications where superconducting qubits are coupled with photons. As this temperature is higher than that of liquid helium (approximately 4 K), this offers the advantage of using relatively simple cryogenic techniques to reach 13 K, boosting application-oriented research using transparent superconductors.

Kumatani, A., Ohsawa, T., Shimizu, R., Takagi, Y., Shiraki, S. & Hitosugi, T. Growth processes of lithium titanate thin films deposited by using pulsed laser deposition. Applied Physics Letters 101, 123103 (2012). | article

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.