11/26/2012

© 2012 American Physical Society

Metals normally have a crystalline structure — that is, the atoms in the material are typically ordered in a repeating pattern. In contrast, atoms in metallic glasses are arranged in no particular long-range order. This disorder endows metallic glasses with a high resilience against deformation, as they lack the natural fault lines along which crystals tend to break. However, crystalline regions have been found to form in some — but not all — metallic glasses when the material is bent. Until now, the reason why these crystalline regions form has remained unclear.

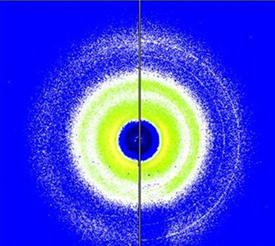

AIMR researchers at Tohoku University together with an international team led by Alain Reza Yavari have now undertaken a combined experimental and theoretical study, and present a model that explains this behavior1. The researchers used an X-ray microscope to examine a ribbon of the metallic glass, Pd40Cu30Ni10P20. As the ribbon was bent, crystalline regions appeared on the side where pressure was applied. This behavior had previously been observed, however the researchers’ use of a high-resolution X-ray microscope enabled a closer, more detailed look at the crystallization process.

The study revealed that compression alone is not sufficient for crystallization to occur. Yavari and co-workers found that a wide supercooled-liquid region is also required to bring about crystallization. This supercooled-liquid region is the range between the temperature at which a glassy metal becomes liquid when heated and the crystallization temperature (typically, far above room temperature). In Pd40Cu30Ni10P20, the material studied by Yavari and co-workers, this region spans about 100 °C. In other metallic glasses, the temperature window is much smaller, or does not exist at all. Thus, in those systems, the phenomenon of crystallization under bending does not develop; instead, cracking and mechanical failure occur.

Yavari and his team’s findings may have the potential for wider application to a broad range of materials. “In our study, the experimental results fit the theoretical predictions very well. This gives us confidence in our model, which suggests that similar processes should be observable for other chemical compositions,” explains Yavari. The model provides important fundamental insights into the properties of disordered metals, but the findings may hold practical significance too. “It is not fully understood how metallic glasses respond to deformations,” says Yavari. "Crystallization phenomena, such as the one we described, lead to a hardening of the material, which may in fact prevent metallic glasses from failing under compression."

Yavari, A. R., Georgarakis, K., Antonowicz, J., Stoica, M., Nishiyama, N., Vaughan, G., Chen, M. & Pons, M. Crystallization during bending of a Pd-based metallic glass detected by X-ray microscopy. Physical Review Letters 109, 085501 (2012). | article

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.