08/30/2010

Portable electronic devices of the future may use a secret ingredient to guard against dents and collisions — a tough new type of alloy called metallic glass. These materials, formed by rapidly cooling molten mixtures of metals, have a non-crystalline, tightly packed internal structure that makes them springier, stronger and more scratch-resistant than conventional crystalline metals. However, the random atomic distribution inside metallic glasses also makes it difficult to optimize their mechanical properties, leading to problems such as shattering and sudden failure.

Mingwei Chen, Pengfei Guan and Takeshi Egami from the WPI-AIMR at Tohoku University have now performed computer simulations that provide new microscopic insights into how mechanical failure occurs in metallic glasses1. The team found that external stress — the act of pulling the material apart — induces a liquid-like ‘flow’ of atoms similar to that caused by an increase in temperature. Their findings uncover the mechanism by which these glassy states can form, with the promise of greatly improving the reliability of manufacture for these alloys.

Despite their rigidity, metallic glasses actually exist in a ‘jammed’ phase of matter that falls between solids and liquids. Forcing hot mobile metal atoms into a mold and then cooling rapidly transforms the liquid into a ‘frozen’ glassy state. It is know that expanding the volume or heating can make the atoms flow once more. Until now, however, the role of external stress on this jammed phase had remained controversial.

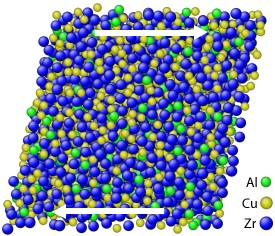

Chen and his co-workers performed their modeling using a computational technique known as molecular dynamics simulation. They simulated the atomic movements in a zirconium–copper–aluminum metallic glass when subjected to a shear force that gradually stretched the glass apart under constant volume and temperature conditions (Fig. 1). After numerous simulations considering a range of shear rates, the researchers observed that the metal atoms entered a state of steady viscous flow, similar to that of a liquid, before snapping apart.

Remarkably, the viscosity of the metal under stress was found to be similar to that associated with elevated temperature, and the researchers were able to model the stress–temperature conditions needed to form either the jammed glassy state or flowing state. The similarity of the effects of temperature and stress indicates that both effects influence atomic flow in a like manner. “This must reflect the simplicity of the dynamics of glasses at a deep level, hidden behind the apparent complexity of the phenomena and the structure,” says Chen.

Guan, P., Chen, M. & Egami, T. Stress-temperature scaling for steady-state flow in metallic glasses. Physical Review Letters 104, 205701 (2010). | article

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.