05/31/2010

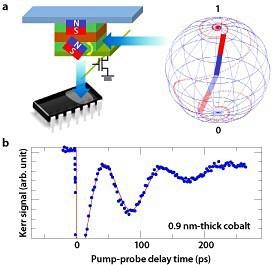

The need for ever-increasing information storage capacity is motivating researchers to investigate various systems for reducing the size of the basic storage elements and increasing the speed at which data can be written and read. A structure that has recently received considerable attention is ‘spin transfer torque’ (STT) magnetic random access memory (MRAM), which is based on arrays of magnetic tunneling junctions. In such a device, the information is stored in the magnetization of a ferromagnetic film, and is controlled by an electrical current applied through the STT interaction. Shigemi Mizukami and colleagues from the WPI-AIMR and Tohoku University1 have now observed the fast motion of spins in a cobalt film just a few atomic layers (0.5–4.0 nm) thick sandwiched between platinum layers. “Spin moves constantly, like a bar magnet, in a memory cell, and it experiences ‘friction’, even though it’s a quantum mechanical object. This friction, called ‘Gilbert damping’, influences power consumption and speed in devices,” says Mizukami. The researcher’s experiments allowed the friction strength acting on the motion of spin in the cobalt film to be determined precisely for the first time (Fig. 1).

In an ideal STT-MRAM element, the minimum current density needed to switch the magnetization should be the lowest physically possible — a value that is proportional to the Gilbert damping constant α, and the perpendicular magnetic anisotropy Heff. However, changes in Heff also affect thermal stability. It is therefore crucial to understand how α and Heff are related in order to design the structures that provide optimal performance.

Previous theoretical investigations have suggested that there is a linear relationship between α and Heff, but this has yet to be confirmed because it is difficult to observe spin dynamics at high frequencies and in ultra-thin films. Mizukami’s team developed a special instrument for performing ultra-fast time-resolved magneto-optical Kerr effect experiments, which allowed the researchers to derive values for both α and Heff.

The results showed that Heff is inversely proportional to the thickness of the cobalt layer, whereas α increases linearly up to a cobalt layer thickness of 1 nm before increasing more rapidly. Mizukami considers that this behavior could reflect the transition from perpendicular to parallel magnetization in the cobalt film. “Our experiments demonstrated that Gilbert damping in the cobalt/platinum system can be tuned widely. It is crucial for spintronics applications to optimize Gilbert damping, while maintaining high Heff, in order to achieve high speed and low power consumption,” says Mizukami. The results therefore represent an important step towards the design of applications based on STT.

Mizukami, S., Sajitha, E.P., Watanabe, D., Wu, F., Miyazaki, T., Naganuma, H., Oogane, M. & Ando, Y. Gilbert damping in perpendicularly magnetized Pt/Co/Pt films investigated by all-optical pump-probe technique. Applied Physics Letters 96, 152502 (2010). | article

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.