Ammonia plays a critical role in food production and industrial development, with a global market size of approximately 175 million tonnes and a market value of $67 billion. Likewise, it is a high-energy-density carrier, making it a key player in the emerging hydrogen economy. The downside to current ammonia production, however, is that synthesis relies heavily on the Harber-Bosch process, which is energy intensive, and results in large CO2 emissions.

Yet, a research group led by Hao Li from Tohoku University’s Advanced Institute for Materials Research (WPI-AIMR) has focused on the electrochemical conversion of nitrate (No3-) to ammonia (NH3), unveiling a process that could potentially revolutionize industrial practices whilst offering new insights into the development of efficient and sustainable catalytic processes.

Details of the findings were published in the journal Advanced Science on August 9, 2024.

“Unlike the nitrogen reduction reaction (NRR), which requires breaking the strong N=N triple bond in nitrogen (N2), nitrate reduction (NO3RR) offers a more efficient pathway,” points out Li. “Nitrate has a much lower dissociation energy and higher solubility in water, making it easier to use as a nitrogen source for ammonia production. This not only enhances the efficiency of the process but also addresses the environmental challenge of nitrate accumulation in water systems.”

Li and his team synthesized a spherical copper (II) oxide (CuO) catalyst, characterized by the stacking of small particles with oxygen -rich vacancies. This catalyst demonstrated a significant enhancement in ammonia yield, achieving 15.53 mg h-1 mgcat-1, with a Faraday efficiency of 90.69% in a neutral electrolyte at a voltage of -0.80 V (vs. reversible hydrogen electrode). Also revealed was that the high catalytic activity of the CuO electrodes stems from both structural and phase changes that occur during the electrochemical reduction process.

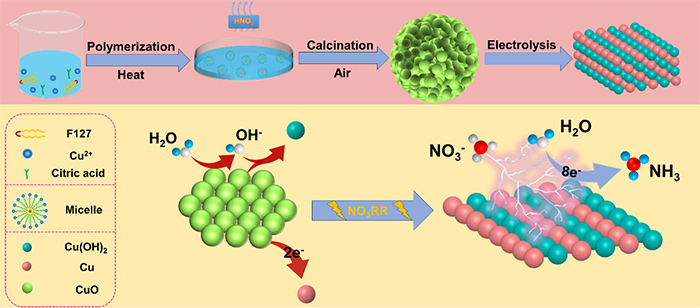

The CuO synthesis route and its reaction process at the cathode. ©Hao Li et al.

“Our research indicates that the transformation of CuO to a Cu/Cu(OH)2 structure during the reaction process is key to the catalyst's performance,” said Qiuling Jiang, a joint PhD student at WPI-AIMR and co-author of the paper. “This phase change not only increases the number of active sites but also improves electron transfer at the electrode surface, enhancing the efficiency of the nitrate reduction reaction.”

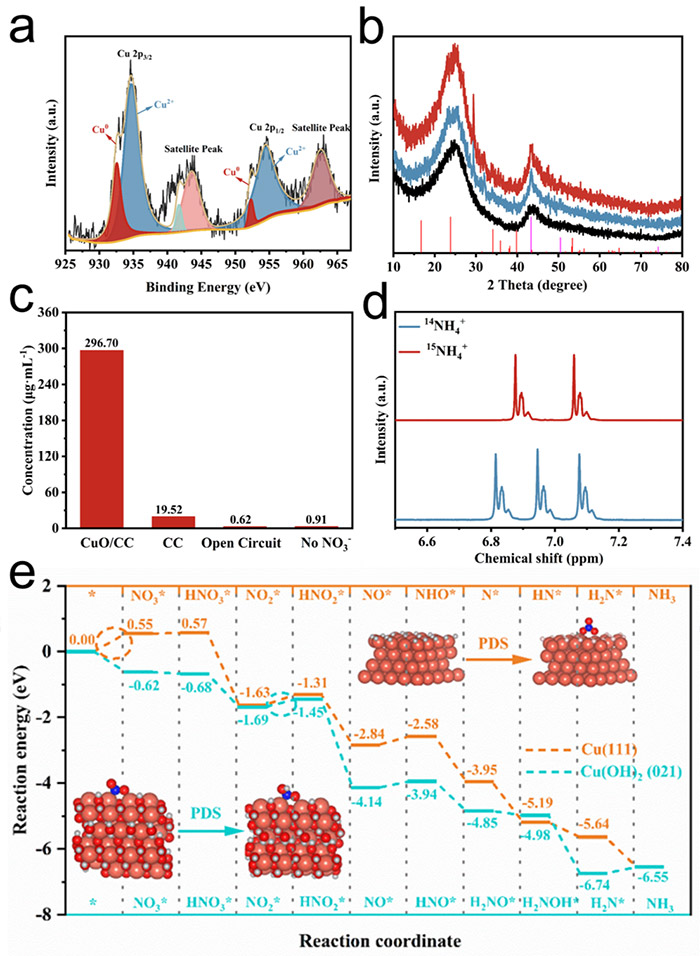

Moreover, the study utilized density functional theory (DFT) calculations to further understand the catalytic mechanism. These calculations showed that the formation of Cu(OH)2 reduces the energy barrier for nitrate adsorption, making the process energetically favorable. Additionally, the Cu(OH)2 phase was found to inhibit the competing hydrogen evolution reaction, while the presence of Cu (111) crystal surfaces facilitated the hydrogenation process.

(a) LSV curves with and without NO3-. (b) Ammonia yield and FE after 2 h i-t electrolysis of CuO500. (c) LSV curves of CuO250 (black), CuO400 (blue), CuO500 (yellow), CuO600 (red), and CuO700 (blue-green). (d) Ammonia yield and FE at -0.80 V after 1 h i-t electrolysis of the material with different calcination temperatures. ©Hao Li et al.

“This research offers a new perspective on the design of copper-based catalysts for electrocatalytic ammonia production,” adds Li. “By controlling the reaction conditions and understanding the phase transitions, we can optimize the catalyst's performance, potentially leading to more efficient and scalable ammonia synthesis processes.”

Looking ahead, the team plans to explore the factors that influence the phase transitions of the catalyst during the reduction process. By further refining these catalysts’ designs, they aim to enhance their stability, activity, and selectivity, bringing the goal of sustainable ammonia production closer to reality.

(a-b) Characterizations of CuO500/CC after electrolysis: (a) Cu 2p XPS and (b) XRD after electrolysis for 1 h (red), 5 h (blue), and CC (black). (c) NH3 concentration of CuO/CC in the presence or absence of NO3-, CC, and open potential conditions at -0.80 V (vs. RHE). (d) 1H-NMR of 14NH4+ and 15NH4+, (e) Calculated free energy diagram of NO3RR on Cu (111) and Cu(OH)2 (021). ©Hao Li et al.

| Title: | Surface Structure Reformulation From CuO to Cu/Cu(OH)2 for Highly Efficient Nitrate Reduction to Ammonia |

|---|---|

| Authors: | in Li, Qiuling Jiang, Xiujing Xing, Cuilian Sun, Ying Wang, Zhijian Wu, Wei Xiong, Hao Li |

| Journal: | Advanced Science |

| DOI: | 10.1002/advs.202404194 |

Hao Li (Profile of Dr. Li)

Advanced Institute for Materials Research (WPI-AIMR), Tohoku University

| E-mail: | li.hao.b8@tohoku.ac.jp |

|---|---|

| Webstie: | Hao Li Laboratory |