Precious metals (Pt and Pd) and rare earth elements (CeO2) are typical materials for heterogeneous exhaust-gas catalysts in automotive systems. However, their limited resources and high market-driven prices are principal issues in realizing the path toward a more sustainable society.

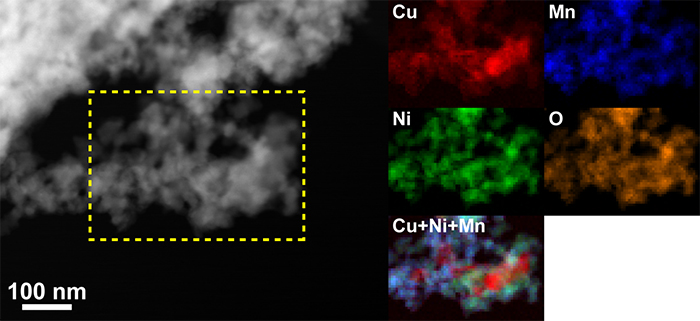

Herein, we have developed an earth-abundant nanoporous NiCuMnO catalyst by leaching Mn from a CuNiMn precursor. The developed catalyst was catalytically active and durable for NO reduction and CO oxidation. During catalytic reactions, the nanostructure was self-transformed into a more active nanostructure; in particular, the Cu/CuO regions derived from the nanostructure were very active, and further significant coarsening was not observed without the loss of activity, as these regions were tangled with a stable nanoporous NiMnO network (Fig.1). The self-transformed nanostructure successfully completed a long-term durability test for NO reduction at 400°C for 10 days. The in situ TEM clearly provided evidence for the instant reaction-induced self-transformation of the nanostructure. The important implication for general catalyst design has been reached.

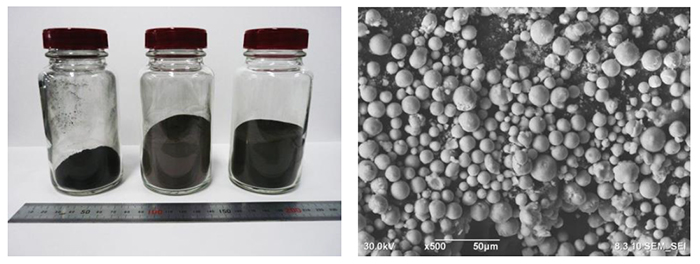

Production of the nanoporous catalysts can be easily scaled up (Fig.2), and they may be a rational alternative to traditional precious-metal catalysts for automotive systems in the near future.

Fig.1 Scanning TEM image and element mapping of the developed nanoporous catalyst.

Fig.1 Scanning TEM image and element mapping of the developed nanoporous catalyst.

Fig.2 Mass production of the developed catalyst.

Fig.2 Mass production of the developed catalyst.

(Left) Appearance in bottles, 400g in total. (Right) SEM image of the gas-atomized micropowders.

JST PRESTO

Research Area “New Materials Science and Element Strategy”

Research Theme “Ubiquitous element based innovative nanoporous metal composite and device”

“Earth-Abundant and Durable Nanoporous Catalyst for Exhaust-Gas Conversion”

DOI: 10.1002/adfm.201504811

For enquires about this research

Prof. Takeshi Fujita

Advanced Institute for Materials Research, Tohoku University

| E-mail : | tfujita@wpi-aimr.tohoku.ac.jp |

|---|

Dr. Hideki Abe

Environmental Remediation Materials Unit, Environment and Energy Materials Division, National Institute for Materials Science

| E-mail : | ABE.Hideki@nims.go.jp |

|---|