09/30/2013

Reproduced, with permission, from Ref. 1 © 2013 American Chemical Society

Biomaterial supports that promote the orderly growth and differentiation of cells are crucial for tissue engineering and repair. However, reproducing the structural and biological properties of the extracellular matrix, which governs cell organization in the body, remains a challenge for materials scientists. Now, Toshinori Fujie and Ali Khademhosseini from the AIMR at Tohoku University and co-workers from Japan, South Korea and the United States have devised a free-standing ultrathin polymer film that mimics the inherent ability of this matrix to direct cells. The resulting ‘nanomembrane’ exhibits nano- and microscale features, similar to those of natural tissue1.

Numerous synthetic extracellular matrices have previously been developed, including hydrogels and elastomers. Unfortunately, unlike their natural counterparts, the size and components of such materials hinder the hierarchical assembly of cells into complex tissue structures.

Using microfabrication techniques, the researchers manufactured their film from nanometer-sized polymer fibers containing cell-adhesive domains, which allowed them to replicate the basement membrane of tissues — a dense, sheet-like structure that serves as a cellular scaffold.

First, they prepared an ultrathin polystyrene film on a glass surface pre-coated with a sacrificial polymer layer. Next, using a microscopic stamp, the researchers patterned the surface of the film with features made from a fibronectin–carbon nanotube composite to functionalize it for cell alignment and adhesion. After cell culture, they then dissolved the initial polymer layer to release the cell-patterned nanomembrane.

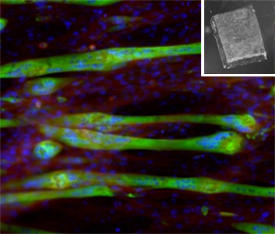

In vitro cell studies showed that the micropatterning facilitated the alignment of muscle progenitor cells, known as myoblasts, on the nanomembrane. The fibrous nanotubes also enhanced the elongation and differentiation of these cells into functional myofibers. “These results suggest that the film’s surface is a useful platform for studying cell−substrate interactions,” says Fujie.

The researchers were able to produce films of various thicknesses — ranging from tens to hundreds of nanometers — by tuning the polystyrene concentration. Analyses of the thickness dependence of the mechanical properties revealed that, in addition to the free-standing films being highly flexible, the thinner films displayed greater flexibility. These unique properties allowed the team to transform the myoblast-coated films into tubular assemblies — without damaging the cells — by rolling them around a soft silicone tube, showcasing the potential of using the nanomembranes as scaffolds in complex tissue architectures.

The team is currently investigating how they can apply these findings to the development of flexible biodevices and tissue regeneration. “The system will be useful for mimicking blood vessels or investigating tissue responses to various drugs and toxic chemicals using lab-on-a-chip devices,” says Fujie.

Fujie, T., Ahadian, S., Liu, H., Chang, H., Ostrovidov, S., Wu, H., Bae, H., Nakajima, K., Kaji, H. & Khademhosseini, A. Engineered nanomembranes for directing cellular organization toward flexible biodevices. Nano Letters 13, 3185–3192 (2013). | article

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.