06/29/2009

Metal alloys with a glassy atomic structure, known as bulk metallic glasses (BMGs), are much stronger than normal metals and have great promise for a variety of applications. Unfortunately, they are also less ductile, making them more susceptible to fracture. To try to understand why, Mingwei Chen and colleagues from the Advanced Institute for Materials Research (AIMR) at Tohoku University1 have conducted the first experimental characterization of shear transformation zones that arise when a BMG is subject to plastic deformation.

When a conventional metal cools from its molten liquid state, its atoms arrange into well-ordered crystalline structures. This rarely results in a perfect single-crystal structure; rather, a polycrystalline matrix consisting of randomly oriented crystallites is generally formed. Owing to the weakness of the boundaries between these grains and other imperfections, the actual mechanical strength of a metal is usually much lower than the theoretical strength it would have if it were a perfect single crystal.

BMGs, on the other hand, are alloys in which the atoms have not been given time to arrange into crystallites, resulting in a non-regular structure similar to that of ceramic glass. This circumvents the problems of grain boundaries and crystal defects, making BMGs much stronger than conventional metals. However, although they are less brittle than ceramics, they are more brittle than most metals.

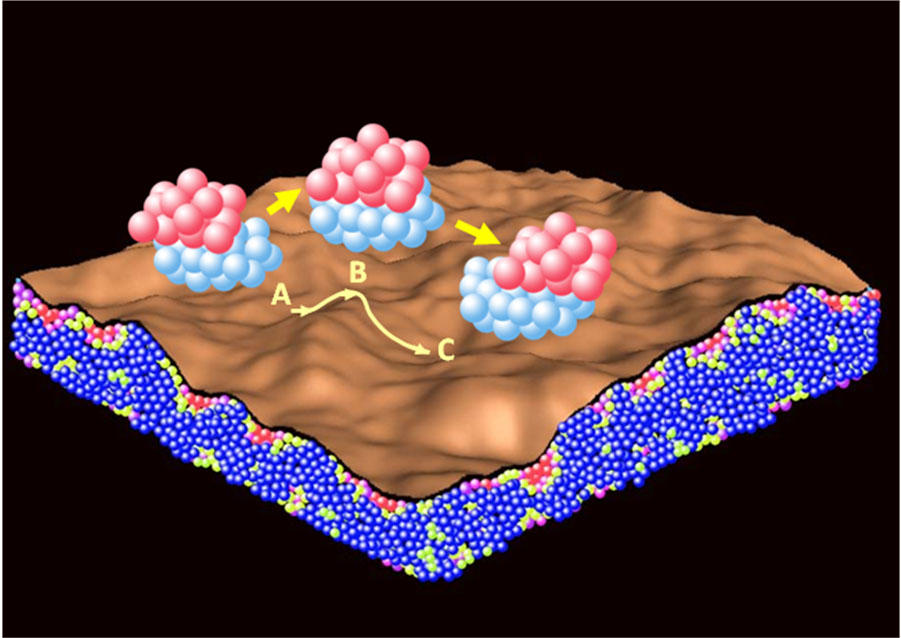

One of the leading explanations for this poor ductility is the emergence of ‘shear transformation zones’ (STZs) within a BMG. STZs are nano-scale volumes of material that undergo plastic flow (Fig. 1), and the concentration of stress at STZs is believed to cause localized shear bands to form, leading to mechanical failure and poor ductility. Until now, the nature or even the exact size of these zones has never been characterized. To address this, Chen and his colleagues developed a new ‘rate-jump nanoindentation’ technique for characterizing the mechanical behavior of these structures involving the measurement and modeling of the response of a BMG to a micro-sized diamond indentor with nanoscopic resolution of force and displacement.

The researchers applied this approach to a variety of different BMGs, which allowed them to determine the volumes of material involved in the plastic flow of atomic clusters in an STZ, and to correlate this with the ductility of the BMG. They found that BMGs exhibiting the smallest STZ volumes were also the least ductile. This observation should allow other scientists to improve their understanding and optimize the mechanical performance of BMGs. It is also a demonstration of a powerful technique for characterizing the mechanical behavior of other non-crystalline materials.

Pan, D., Inoue, A., Sakurai, T. & Chen, M.W. Experimental characterization of shear transformation zones for plastic flow of bulk metallic glasses. Proceedings of the National Academy of Sciences 105, 14769–14772 (2008). article

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.