Research

Concept & Approach

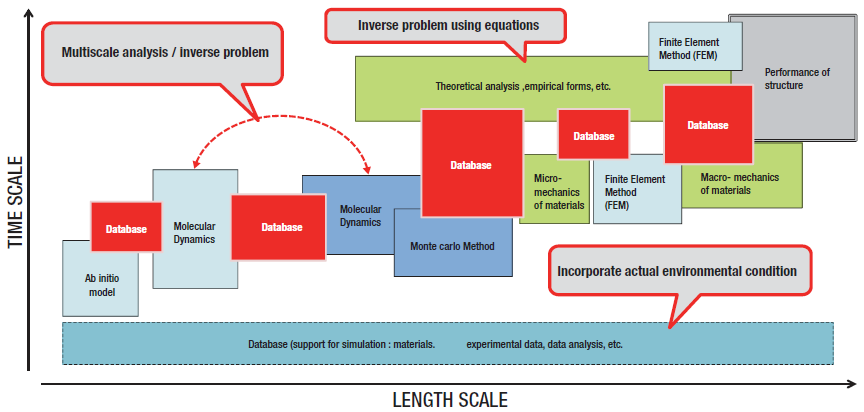

Materials Integration (MI) for engineering polymer materials combines different length scale and time scale behaviors via a new database system. The MI system is expected to understand the relationship between processing, structures, properties and performance of the engineering polymer materials from any length scale and time scales. Materials Integration for engineering polymers aims to bridge all scientific knowledge and tools of related fields. The tools include analysis, simulations, experiments, empirical forms, etc.

Unique formation of research fields in the researchers in MI for engineering polymers covers mathematics, medicine, materials science, chemistry, physics, etc. Inverse problems is expected to solve using the MI system, this is especially effective for shortening of R&D time of related materials fields.

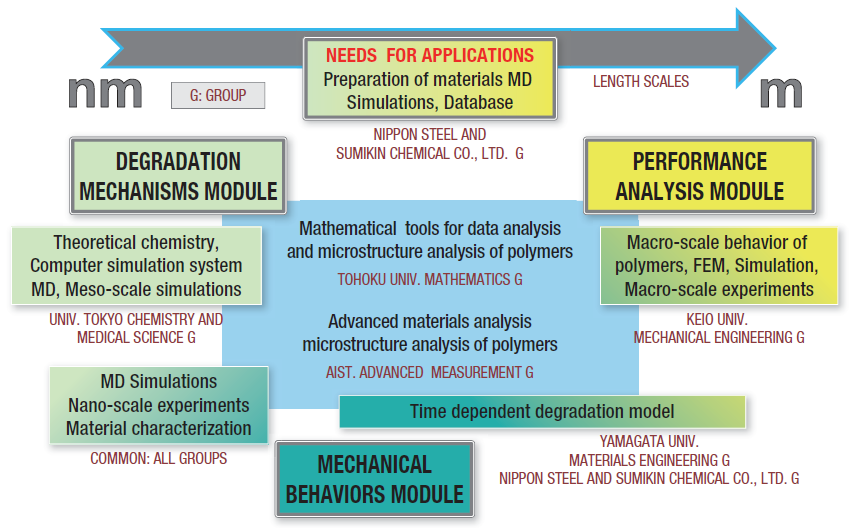

Team Members and Roles

The team organization for Materials Integration of polymer materials is performed following the selection of individual research proposals. Thus, members did not know the actual task before team formation. This point is especially important to achieve the high potential MI systems for engineering polymers. The team is expected to bring new approaches and to form integration of research fields to achieve the goals of the MI system. Understanding of real engineering problems through the developed MI system is designed to address use industrial applications using open built-in databases and closed individual databases prepared by the user companies.

Research and Development of Polymer MI

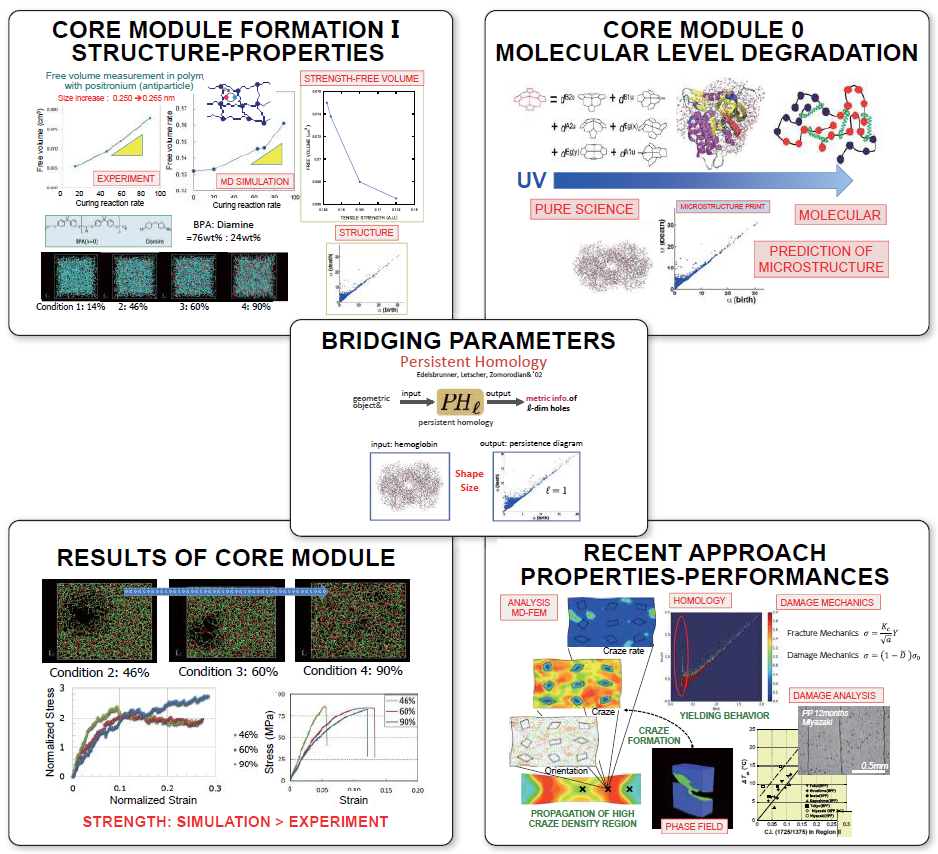

Initially, we focused on structural epoxy polymers and prepared some model epoxy resin samples. Mechanical tests, positron annihilation-based free volume measurements, nano-palpation atomic force microscopy (AFM) analysis, and full atom and coarse-grained molecular dynamics (MD) simulations were conducted to clarify the relationship between molecular structures and mechanical properties. Additionally, the material heterogeneities were quantified via persistent homology analysis. Then, databases were created based on these results and applied to solve inverse problems.

The effects of conversion on mechanical properties were confirmed by subjecting the polymer samples to mechanical tests. The free volumes of the polymer samples increased as their conversion by positron annihilation increased. This finding is in good agreement with the MD simulation results.

The heterogeneities of the polymer materials are reflected in dynamic systems of the structural materials, including their fracture and damage mechanics. Therefore, we aim to develop a polymer materials integration (MI) system consisting of practical modules that can be used to correlate the spatial and temporal scales.

In addition to the conventional approaches used to study polymers, the development of approaches based on fresh perspectives has been enabled through the combined efforts of many researchers with expertise in various scientific and technological fields. Thus, our research and development have evolved, and we now pursue high-level, novel polymer MI studies. For example, the use of mathematical approaches enables combining different technical elements to define the components of polymer materials.