|

||

|

||

Research on Advanced Non-equilibrium Metallic Materials At WPI-AIMR we develop and study ultrahigh-strength metallic and dual-phase (crystalline-metallic glassy, metallic glassy-polymer, metallic-oxide glassy) functional and structural materials. We discover new horizons of synergetic research between materials science, mathematics, chemistry, physics and biology, creating a new generation of lightweight high specific strength structural as well as functional (optical and magnetic), chemical (catalytic) and biological (implants) materials for improving life standards and saving our natural environment by reducing fuel consumption using lighter and stronger materials.

|

||

Crystal nucleation and growth processes in Cu-rich glass-forming Cu–Zr alloys The glass-formation of Cu-Zr alloys (Zr fraction from 1 to 10 at.%) was studied by MD simulation in line with the nucleation and growth of a FCC Cu crystalline phase. We found that the critical cooling rate increases by two orders of magnitude from 0 to 5 at.% Zr and is extrapolated to drop to 1E7-1E8 K/s for the Cu90Zr10 alloy. Notwithstanding the negligible equilibrium solid solubility of Zr in FCC Cu, the growing Cu crystals are found to dissolve some amount of Zr with an overall metastable solubility limit of 4.4 at.% Zr. The growing FCC crystals have a nearly spherical morphology. In alloys containing up to 6 at.% Zr, a supersaturated FCC Cu solid solution grows polymorphically while in alloys with higher Zr content, a Zr concentration gradient is observed in the FCC Cu region. At 9 at.% of Zr and more the concentration gradient starts directly from the interface at 773 K and from the liquid phase at 900 K. In spite of diffusional redistribution of the alloy components at high Zr content, the crystal growth rate before crystal impingement is nearly constant in all alloys (though somewhat increases with time), while it decreases exponentially with Zr content. There is a critical concentration of 3 at.% Zr at which the slope in dlog(U)/dCZr is changed, likely related to reduction of the number of stacking faults in crystalline Cu (Fig. 1).

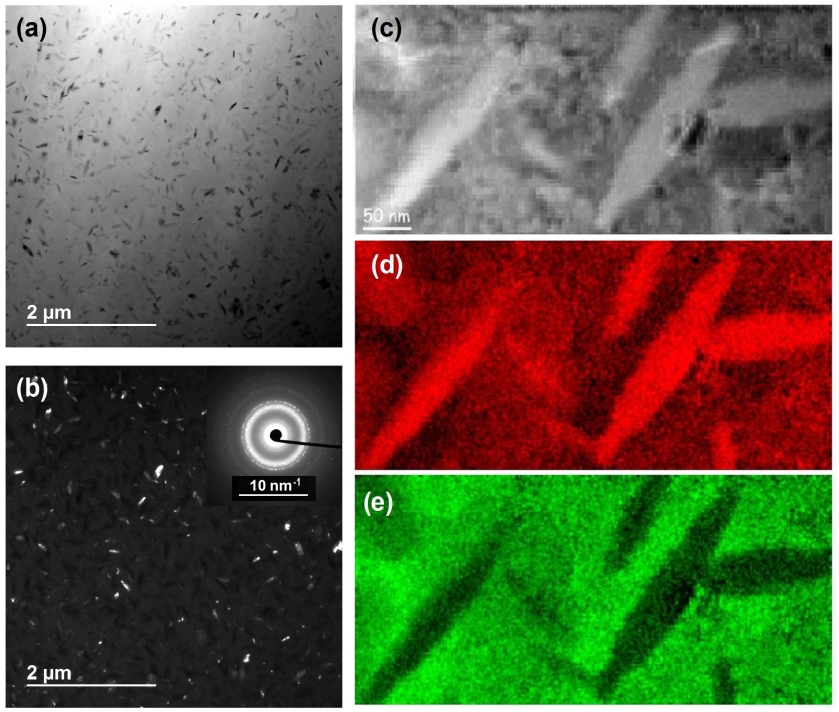

Fig. 1. Crystal growth rate as a function of Zr content.. A. K. A. Lu and D. V. Louzguine-Luzgin, Crystal nucleation and growth processes in Cu-rich glass-forming Cu–Zr alloys, J. Chem. Phys. 157, 014506 (2022). DOI: 10.1063/5.0097023. Long-range-diffusion-assisted but interface-controlled crystallization of a metallic glass below its glass-transition temperature A metallic glass of nominal composition Mg75Ni20Mm5 (Mm: mischmetal) when heated shows primary crystallization to Mg2Ni. Transmission electron microscopy studies, including annealing experiments in-situ, supported by differential scanning calorimetry and X-ray diffraction, reveal the remarkable complexity of this crystallization. The crystals are lens-shaped and at constant temperature show linear (constant-rate) growth, despite marked partitioning of nickel from the glass to the crystal. The growth, constrained by atomic rearrangement at the glass-crystal interface, gives a crystalline phase that is partially disordered and has almost half of its magnesium sites vacant (Fig. 2). The combination of solute partitioning and isothermal linear growth challenges usual assumptions about the characteristics of primary and polymorphic crystallization. This hybrid behavior is interpreted in terms of the widely differing diffusivities of the atomic species in this system.

Fig. 2.Bright-field (a) and dark-field (b) TEM images of crystallites embedded in the residual glassy matrix, and SAED pattern (inset). High angle annular dark field (HAADF) image (c) and EDX maps for Ni (d) and Mg (e). The RE elements are homogeneously distributed in the entire sample. The sample was annealed isothermally at 431 K for 480 s. From EDX analysis, the residual glassy matrix has average elemental contents of 79 at.% Mg and 16 at.% Ni, while the crystals have 48 at.% Mg and 47 at.% Ni. . Yu.P. Ivanov, V.O. Semin, Z. Lu, J. Jiang, A.L. Greer, D.V. Louzguine-Luzgin, Long-range-diffusion-assisted but interface-controlled crystallization of a Mg-Ni-Mm glass below its glass-transition temperature, Journal of Alloys and Compounds, Vol. 909, (2022), 164732. DOI: 10.1016/j.jallcom.2022.164732.

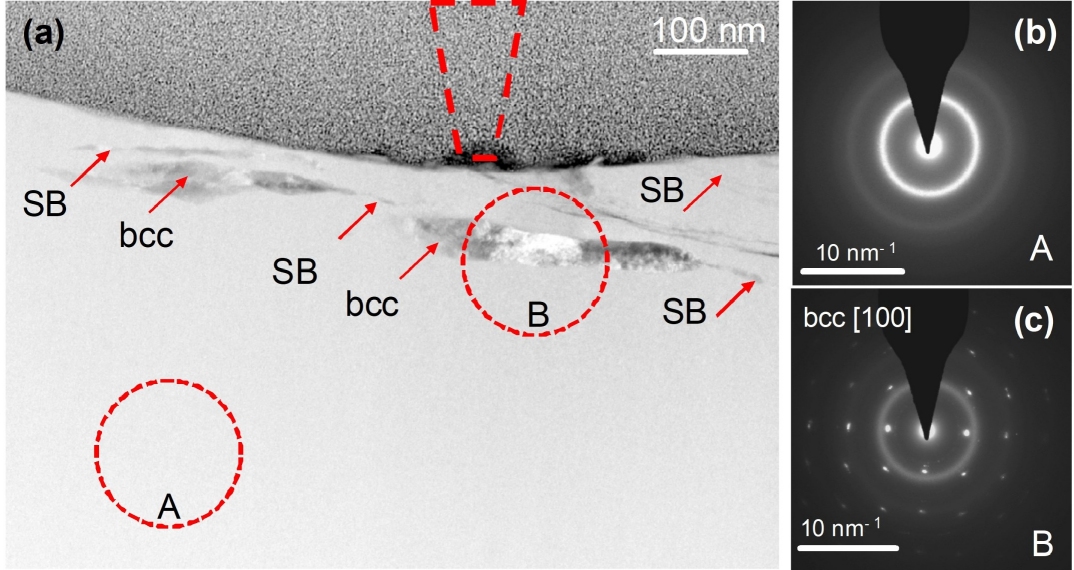

Shear-induced chemical segregation in a bulk metallic glass at room temperature Shear-induced segregation, by particle size, is known in the flow of colloids and granular media, but is unexpected at the atomic level in the deformation of solid materials, especially at room temperature. In nanoscale wear tests of an Fe-based bulk metallic glass at room temperature, without significant surface heating, we find that intense shear localization under a scanned indenter tip can induce strong segregation of a dilute large-atom solute (Y) to planar regions that then crystallize as a Y-rich solid solution (Fig. 3). There is stiffening of the material, and the underlying chemical and structural effects are characterized by transmission electron microscopy. The key influence of the soft Fe-Y interatomic interaction is investigated by ab-initio calculation. The driving force for the induced segregation, and its mechanisms, are considered by comparison with effects in other sheared media.

Fig. 3. Cross-sectional TEM observation of a wear track. (a) HAADF STEM image of the cross-section of the track after ten to-and-fro passes, showing the MG matrix and within it shear bands (SBs) and bcc crystals. The position and size of the AFM tip is indicated by the dashed cone located at the center of the track, which overall is 650‒750 nm wide. (b) and (c) are SAED patterns from regions A and B, respectively, indicating a glassy phase and a crystal induced by mechanical deformation. D. V. Louzguine-Luzgin, A. S. Trifonov, Yu. P. Ivanov, A. K. A. Lu, A. V. Lubenchenko & A. L. Greer, Shear-induced chemical segregation in a Fe-based bulk metallic glass at room temperature, Scientific Reports, Vol. 11, (2021) 13650.

|

||

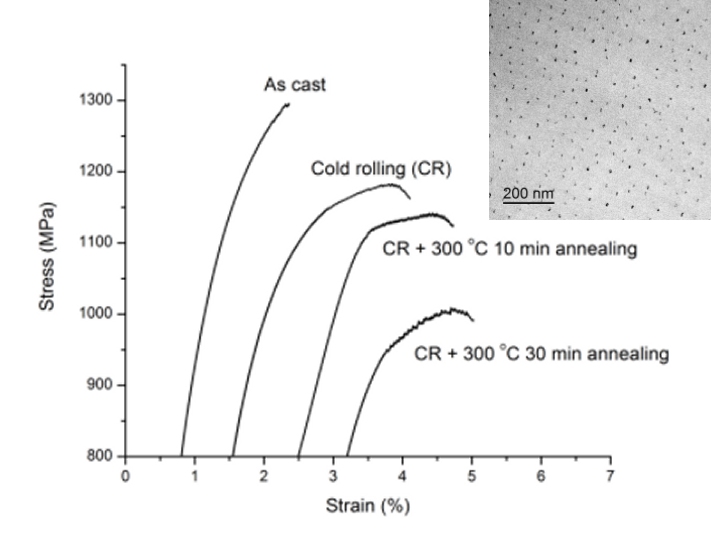

Thermo-mechanical processing of a bulk glassy alloy as a way to obtain tensile ductility Low plasticity is a key drawback limiting the widespread use of bulk metallic glasses. Although heat treatment and thermo-mechanical processing techniques are not applied to metallic glasses (only to supercooled liquids), since heating leads to embrittlement due to structural relaxation or thermal crystallization, we demonstrate a strong positive effect of cold rolling and subsequent thermal annealing below the glass-transition temperature on room-temperature mechanical properties of a Zr62.5Cu22.5Fe5Al10 glassy alloy (Fig. 4). As a result we observed softening and appearance of tensile ductility (up to 1.5 %) in bulk samples and an increase in hardness by up to 25 % in ribbon samples yet retaining good bending plasticity. The proposed method can be applied to a number of amorphous alloys.

Fig. 4. Tensile test stress-strain curves of bulk samples in the as-cast, cold rolled and thermo-mechanically treated states. A.I. Bazlov, A.G. Igrevskaya, N. Yu Tabachkova, C. Chen, V.V. Cheverikin, A.V. Pozdniakov, J. Jiang, D.V. Louzguine-Luzgin, Thermo-mechanical processing of a Zr62.5Cu22.5Fe5Al10 glassy alloy as a way to obtain tensile ductility, Journal of Alloys and Compounds, Vol. 853 (2021) 157138. |

||

An atomistic study of the structural changes in a Zr-Cu-Ni-Al glass-forming liquid on vitrification monitored in-situ by X-ray diffraction and molecular dynamics simulation

Structural changes in the Zr55Cu30Ni5Al10 liquid alloy on cooling from above the equilibrium liquidus temperature are studied by synchrotron radiation X-ray diffraction and compared with the results of first-principles molecular dynamics simulation. In-situ vitrification of the studied alloy is achieved using a containerless levitation technique. Subsequent analysis of the atomic and electronic structure of the alloy in liquid and glassy states reveals formation of medium-range order on cooling and its relationship with liquid fragility (Fig. 5). It is concluded that fragility is a sign of instability of short and medium range order in fragile liquids.

Fig. 5. Tne areas (AP1/AP2) ratio for P1 and P2 peaks of the atomic pair-distribution function in the first coordination shell as a function of temperature and inverse temperature. D.V. Louzguine-Luzgin, K. Georgarakis, J. Andrieux, L. Hennet, T. Morishita, K. Nishio, R.V. Belosludov, An atomistic study of the structural changes in a Zr–Cu–Ni–Al glass-forming liquid on vitrification monitored in-situ by X-ray diffraction and molecular dynamics simulation, Intermetallics, Vol. 122 (2020) 106795. DOI: 10.1016/j.intermet.2020.106795. |

||

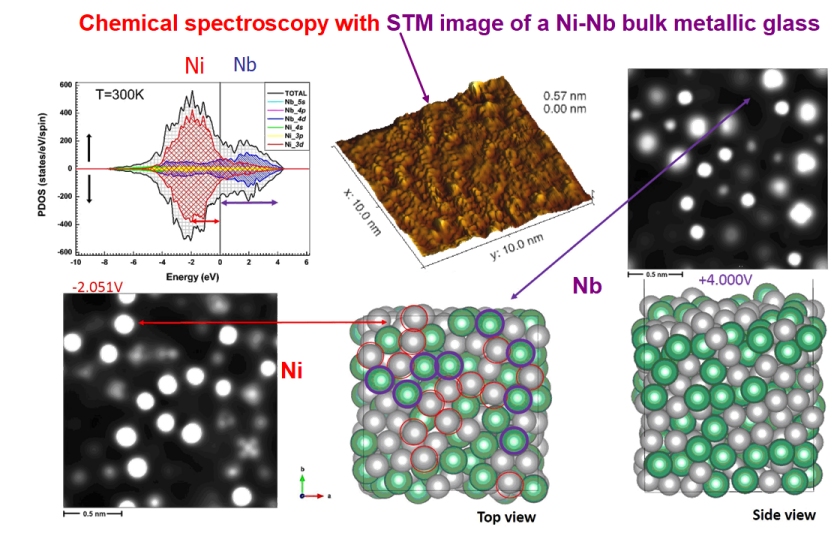

The atomic structure of a bulk metallic glass resolved by scanning tunneling microscopy and ab-initio molecular dynamics simulation Scanning tunneling microscopy (STM) technique is widely used to study the electronic and structural properties of nano structures. Here we study the atomic structure of a Ni-Nb BMG by means of ultra high vacuum (UHV) STM in local areas of nanometer scale size, and report the direct atomic structure observation supported by ab initio molecular dynamics (MD) and density functional theory (DFT) simulations used to understand the observed structural and electronic features. It was possible to resolve the atomic surface structure of a bulk metallic glassy sample while MD simulation explained relatively large interatomic distances observed using STM (Fig. 6). The constructed PDOS allowed explaining relatively large interatomic distances observed using STM compared to those found by XRD. Such a behavior is related to the electronic interaction between the tip and the constituent elements of the metallic glass leading to the situation when only Ni atoms are visible at the applied potential (negative bias voltage).

|

||

Fig. 6. Total and partial density of states (a), as well as the STM images calculated at the bias of (b) -2.051 V and (c) +4.00 V. (d) and (e) are top and side views of atomic configuration of the Ni-Nb glassy alloy surface. The Ni63.5Nb36.5 configuration was modeled within a cubic supercell consisting of 400 atoms within the Vienna ab initio Simulation Package (VASP). R.V. Belosludov, A.I. Oreshkin, S.I. Oreshkin, D.A. Muzychenko, H. Kato, D.V. Louzguine-Luzgin, The atomic structure of a bulk metallic glass resolved by scanning tunneling microscopy and ab-initio molecular dynamics simulation, Journal of Alloys and Compounds, Vol. 816, (2020) 152680. |

||

|

||

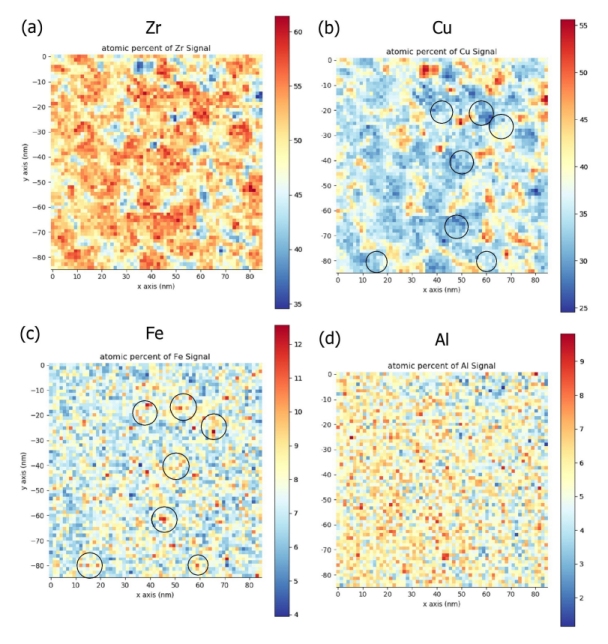

Phase separation process prevents thermal embrittlement of a bulk metallic glass Annealing below the glass-transition temperature usually leads to structural relaxation and densification of the glassy alloy which in turn cause embrittlement of the glassy phase. However, the studied Zr63Cu22Fe5Al10 metallic glass even in the relaxed state exhibits nearly as high plasticity as in the as-cast state. Also, no hardening but even mechanical softening is observed after annealing even though the samples showed a reduction in size and volume typical for fully relaxed Zr-based alloys. The reason for such behavior is connected with nanoscale phase separation at about 10 nm lengthscale within the glassy phase which is comparable in size to the width of shear bands. Formation of Cu- and Zr-rich areas on annealing at low temperature is also suggested by thermodynamic calculations while Al is homogeneously distributed (Fig. 7). Fe is also placed in antiphase with Cu and likely further promotes phase separation.

Fig. 7. The elemental maps for Zr, Cu, Fe and Al (a-d), respectively, plotted for the Zr-Cu-Fe-Al sample annealed for 1 h at 623 K. D.V. Louzguine-Luzgin, J. Jiang, A.I. Bazlov, V.S. Zolotorevzky, H. Mao, Yu P. Ivanov, A.L. Greer, Phase separation process preventing thermal embrittlement of a Zr-Cu-Fe-Al bulk metallic glass, Scripta Materialia, Vol. 167, (2019), pp. 31-36. DOI: 10.1016/j.scriptamat.2019.03.030. |

||

|

||

Local chemical ordering within the incubation period as a trigger for nanocrystallization Nanocrystallization of the Ti50Ni23Cu22Sn5 alloy was studied within the supercooled liquid region by using a state-of-the-art experimental technique with elemental mapping at near-atomic resolution especially focusing on the incubation period which is still poorly understood from both the theoretical and experimental viewpoint. The experiment and MD results indicate formation of nanometer-range chemical rearrangements (Fig. 8) which are supposed to reduce the energy barrier in the complex energy landscape finally leading to a high density of homogeneously nucleating crystallites after the completion of a macroscopically observed incubation period. |

||

|

||

|

||

Fig. 8. HAADF (as marked) and STEM-EDS mapping per element of the Ti50Ni23Cu22Sn5 sample annealed at 753 K for 40 s. |

||

Z. Wang, C.L. Chen, S. V. Ketov, K. Akagi, A. A. Tsarkov, Y. Ikuhara, D. V. Louzguine-Luzgin, Local chemical ordering within the incubation period as a trigger for nanocrystallization of a highly supercooled Ti-based liquid, Materials & Design, Vol. 156, (2018), pp. 504-513. |

||

|

||

Mechancial rejuvenation Loading millimetre-scale samples of the Zr61Cu27Fe2Al10 bulk metallic glass in uniaxial compression at room temperature, and applying 10 cycles of 50±37.5% of the yield stress, induces detectable and quite complex changes in properties. The relaxation and crystallization enthalpies of the sample increased as a result of structural rejuvenation. The excess specific heat capacity, dCp = 1.85 J/molK, of an elastically cycled glass over an as-cast glass also suggests that cycling takes the metallic glass into a more excited state (Fig. 9). Considering both the present results on cyclic loading and earlier reports on static loading, it appears that loading of metallic glasses in the nominally elastic range generally induces structural states of higher, not lower, energy. Changes in Young’s modulus suggest that, in both as-cast and annealed samples, compressive loading induces anisotropy. Such an effect is also observed in the relaxed glass which in addition showed a high Young’s modulus close to that of crystals whereas its hardness is only slightly affected.

Fig. 9. DSC traces indicating the difference in Cp values between the supercooled liquid and glass in as-cast state, immediately after elastic cycling as well as 3 and 7 days later. D.V. Louzguine-Luzgin, V. Yu. Zadorozhnyy, S.V. Ketov, Z. Wang, A.A. Tsarkov and A.L. Greer, On room-temperature quasi-elastic mechanical behaviour of bulk metallic glasses, Acta Materialia, 129 (2017) 343–351. |

||

Cryogenic cycling rejuvenation Cryogenic thermal cycling of metallic glasses induces rejuvenation, reaching the states of higher energy (Fig. 10). It originates from the heterogeneous dynamics in liquids leading to the heterogeneities in the glasses. Thermal cycling is a non-destructive, isotropic and controllable method which induces no macroscopic residual stresses.

Fig. 10. Differential scanning calorimetry traces of melt-spun ribbons of the La55Ni20Al25 and bulk rods of the La55Ni10Al35 metallic glasses indicating the increased heat of structural relaxation. S. V. Ketov, Y. H. Sun, S. Nachum, Z. Lu, A. Checchi, A. R. Beraldin, H. Y. Bai, W. H. Wang, D. V. Louzguine-Luzgin, M. A. Carpenter and A. L. Greer, Rejuvenation of metallic glasses by non-affine thermal strain, Nature, 524 (2015) 200–203.

|

||

|

||

Patents: 1.

謝国強、 井上明久、 ルズギン ドミトリー バレンチノビッチ、 木村久道、李松、 「金属ガラス複合構造物及び金属ガラス複合構造物の製造方法」

、特許出願日: 2009年4月24日、 出願番号: 特願2009-107145. |

||

|

||

|