11/25/2019

© 2019 Hiroshi Yabu and Hiroya Abe

A new class of platinum-free catalysts that could lead to cheaper fuel cells has been designed by researchers at the AIMR1. These catalysts have catalytic activities that surpass those of even ones containing platinum, and can be produced under mild conditions at low cost.

Hydrogen fuel cells, which generate electricity by reacting hydrogen and oxygen to produce water, are highly attractive clean power sources for electric vehicles and domestic appliances. But one obstacle for their commercial adoption has been the fact that the most effective catalysts for the oxygen-splitting reaction that occurs on their cathodes are expensive because they contain the precious metal platinum. The same problem arises in metal–air batteries.

With a view to reducing the cost of fuel cells, material scientists have been searching for stable platinum-free catalysts that have high catalytic activities.

Now, Hiroshi Yabu and Hiroya Abe at the AIMR at Tohoku University and their co-workers have developed catalysts that tick all the boxes — they are made from low-cost materials, are easy to make, have a high catalytic activity, and show good stability.

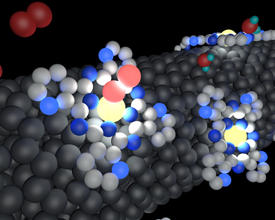

The team made the catalysts by coating multiwalled carbon nanotubes with a single layer of molecules of iron azaphthalocyanines, complexes consisting of an iron atom surrounded by four interconnected aromatic rings.

The researchers had not expected their catalysts to be as effective. “We were surprised that we could realize a catalytic activity superior to that of platinum-based catalysts by just swapping the peripheral benzene groups of phthalocyanine with pyridine groups and adsorbing this compound on carbon nanotubes,” notes Yabu. “Indeed, as far as we’re aware, this is the highest activity obtained for conventional catalysts based on modified carbon nanotubes.” The researchers found that this high activity is due to the favorable positioning of nitrogen atoms in the azaphthalocyanine rings.

The catalysts have the added advantage that, unlike other platinum-free catalysts, they do not require high temperatures to manufacture. “Our phthalocyanine derivative dissolves in organic solvents and is easily absorbed onto the carbon nanotubes,” says Yabu. “This is a great advantage compared with catalysts made by pyrolysis, which require complex, high-temperature processes and good control of the process conditions.”

The team has established a new company to supply the catalysts worldwide. Furthermore, they are performing theoretical calculations to try to find other phthalocyanine derivatives that have even higher catalytic activities. “We believe this kind of collaboration, involving both theory and experiment, will lead to the development of many more highly functional materials,” says Yabu.

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.