03/25/2019

© 2019 Gang Huang

A strong, porous material developed by AIMR researchers has the potential to dramatically increase the amount of energy lithium batteries can store1, enabling more time between charging mobile devices.

Rechargeable lithium-ion batteries are widely used to power electronic devices and electric vehicles. Lithium ions stored on their electrodes during charging are subsequently released during discharging. One of these electrodes, known as the anode, is typically made from graphite, an inexpensive form of carbon that is used in pencil lead. However, graphite accommodates a relatively small amount of lithium ions.

Anodes made from lithium metal have a much higher capacity, but they suffer from two problems. As lithium moves in and out of the anode, thin metal whiskers, called dendrites, start to sprout from it. The flow of lithium also causes the anode expand and contract. Both effects rapidly curb the battery’s efficiency, and can even cause combustion.

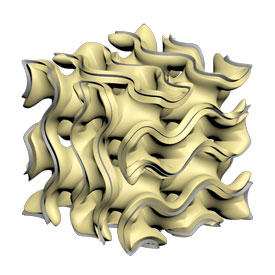

A team led by Mingwei Chen of the AIMR at Tohoku University has now shown that anodes made from nanoporous graphene doped with nitrogen can host much more lithium than graphite. The material is also lightweight, flexible and highly conductive, making it promising as a battery anode.

The researchers grew the material inside a porous nickel template, before etching the metal away. Its porous structure gave nitrogen-doped graphene an extremely low density, enabling it to store large amounts of lithium without adding much weight to a battery. Its layered sheets of carbon atoms were peppered with nitrogen atoms, which helped to bind lithium.

After infusing the material’s pores with lithium, the researchers found that the anode could undergo more than 700 charge–discharge cycles without any significant loss in performance, more than four times as many cycles as a pure lithium electrode. “I was really surprised by its ultrahigh stability,” comments Gang Huang, a member of Chen’s team.

Scanning electron microscope images revealed that dendrites did not grow on the anode, and its volume varied little on charging and discharging.

Furthermore, the charge storage capacity of the anode was a mere 10% lower than the theoretical maximum capacity of a pure lithium metal electrode. “The specific capacity of our nanoporous anode is nearly 10 times greater than the graphite electrodes typically used in lithium-ion batteries,” notes Huang.

A battery containing the anode had a high charging rate and consistently outperformed a rival with a pure lithium anode. The researchers hope to apply the same anode design to other metal-electrode batteries, such as those using sodium or magnesium.

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.