04/25/2014

© 2014 Yonghao Zheng

Single crystals of polymers can be difficult to obtain because their long and flexible backbones tend to get tangled, forming structures with no long-range order. However, the process of preparing these polymers is eased if polymerization takes place inside a molecular crystal in which the reactive monomers are pre-organized in a position that almost corresponds with the repeat distance of the desired polymer. The confinement of these monomers during polymerization yields long single-polymer chains.

Researchers from the AIMR at Tohoku University and the University of California have used this approach to synthesize a new class of polymers1. They constructed two new polymers from bis(indenedione) monomers, which are highly colored conjugated organic dyes.

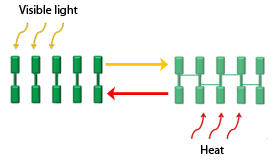

Polymerization ordinarily requires heat, ultraviolet light or pressure. In contrast, the researchers used visible light to induce the reactions between the monomers and produce the new polymers (see image). “This is the first time that the quantitative conversion of a small molecule to a macromolecule has been achieved with visible light,” says Yonghao Zheng, a member of the research team.

Unlike the monomers they were constructed from, the polymer strands are colorless because polymerization breaks the monomers’ conjugation. The progress of the reaction can therefore be seen with the naked eye. The researchers shone light on the molecular crystal, causing the top layer of the crystal to polymerize and become transparent. Light can then pass through to the next layer, which subsequently undergoes polymerization. This continues until the entire crystal is colorless. The researchers were able to isolate individual polymer strands by applying and then removing sticky tape from the polymerized crystal.

The resulting polymers are strong, explains Zheng. “One possible application is as a strengthening component in composite materials.” The polymers lose their translucency when heat is applied, breaking them down to their component parts, which allows any weaknesses to be spotted.

The researchers also showed that single chains of the two polymers could be made inside molecular crystals dissolved in highly concentrated solutions, as well as on semicrystalline thin films. These synthetic methods are well-suited to manufacturing, thereby opening up this class of polymers to a wide range of applications. “The feature of polymerization on thin films is of great potential for solution-processing applications in organic electronics, such as thin-film transistors,” says Zheng.

The researchers now plan to focus on unfolding the fundamental properties of single chains of polymers and are currently studying their mechanical properties.

Dou, L., Zheng, Y., Shen, X., Wu, G., Fields, K., Hsu, W.-C., Zhou, H., Yang, Y. & Wudl, F. Single-crystal linear polymers through visible light–triggered topochemical quantitative polymerization. Science 343, 272–277 (2014). | article

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.