04/30/2012

© 2011 ACS

The surfaces of polymers — large molecules comprising repeated structural units — contain special physical properties such as adhesion, wetting, and friction. These properties can be quite different from those of the bulk material, and are difficult to correlate with the polymers’ molecular structures. Although modern synthetic strategies offer much control over molecular structure, finding the optimum polymer for a particular device or application remains a challenge. Ken Nakajima, Dong Wang and co-workers1 from the WPI-AIMR at Tohoku University have now succeeded in mapping out the surface properties of a polymer film using atomic force microscopy (AFM).

Nakajima describes the concept of mapping properties with a simple illustration: “Consider painting a colored ink on a polymer surface — the color will be more easily erased from areas with lower adhesive properties.” Polymer properties such as viscoelasticity and adhesion hold great potential in a variety of applications, including automotive manufacturing. “It is clear that this work may be directly applicable in the production of polymer materials for tires, for which adhesive and viscoelastic properties are important. Indeed, we are currently collaborating with several tire companies in Japan,” says Nakajima.

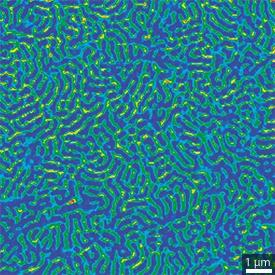

In the past, measurements of tensile or shear stress have been used to evaluate adhesive strength and viscoelastic behavior. These methods, however, are a macroscale examination and provide only an average value of properties. In contrast, AFM uses an atomically thin tip attached to a flexible lever to directly probe the properties of the surface at the nanoscale. Here the research team used contact-mode AFM, described by Nakajima as “a nanomassage” in which the polymer’s molecular structure consists of a block of poly(ethylene-co-butylene) sandwiched between two blocks of poly(styrene) — a tri-block copolymer. Rather than being homogenously mixed, the polymer molecules in the bulk are arranged so that ‘blocks’ of similar polymer are close together. At the surface, this is manifested as a pattern of many small polymer ‘islands’ (see image). “Our AFM technique allows us to prepare a map of how the surface properties vary over the surface,” explains Nakajima.

This technique holds promise in the mapping of mechanical surface properties for other types of block co-polymer, provided there is a mechanical difference between the different components. “In the future we hope to characterize the surface properties of other materials such as bulk metallic glasses and biomaterials,” says Nakajima. “Ultimately we are hoping to establish a connection between the macroscopic properties of the polymer and a nanoscopic understanding of structure which we can then use to evaluate and design new high performance materials.”

Wang, D., Liang, X-B., Liu, Y-H., Fujinami, S., Nishi, T. & Nakajima, K. Characterization of surface viscoelasticity and energy dissipation in a polymer film by atomic force microscopy. Macromolecules 44, 8693–8697 (2011). | article

This research highlight has been approved by the authors of the original article and all information and data contained within has been provided by said authors.